Description of the Roller Shutter Roll Forming Machine

The TRFM ISO CE-certified roll-up door machine is designed for producing metal shutter doors at speeds of 15 to 45 m/min, with customizable options available.

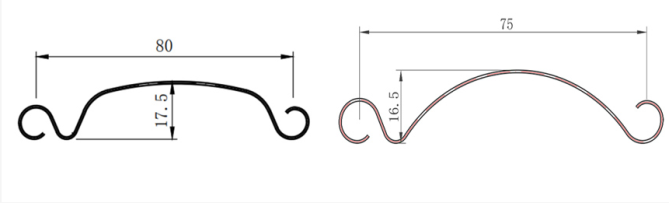

This rolling door machine series is specialized for manufacturing various rolling shutter door panels. Beyond forming, the machine integrates punching and embossing functions, and profiles can be customized based on customer needs.

As a trusted manufacturer, Cangzhou Roll Forming Technology employs advanced production technology and strict quality control to ensure consistent high-quality output.

For details on pricing and specifications, please contact us.

Features and Benefits of Shutter Door Machine

Production Speed: Options of 20, 30, 40, 50, or 60 meters per minute.

Efficiency: Non-stop flying cut and automatic stacking enable up to 60 m/min.

Flexibility: Quick-change cassette design accommodates multiple profiles.

Certifications: CE-certified and patented for European standards.

Stock Availability: Popular models are available for quick delivery.

Application pictures of rolling shutter door structures

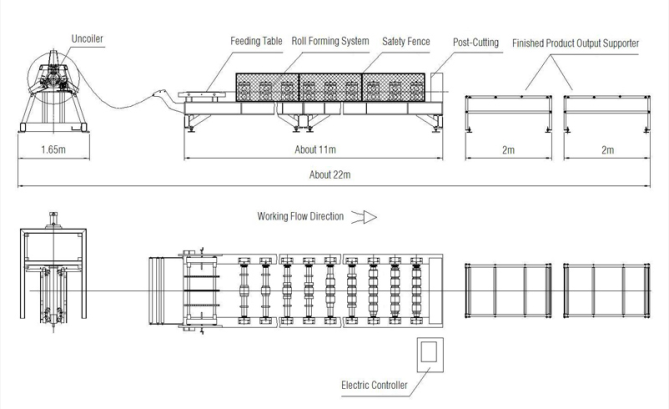

Workflow:

Decoiler (manual/auto) → Feeding and Guiding Table → Leveling → Punching (if needed) → Pre-cutting → Roll Forming → Output with Manual/Automatic Stacker.

The Technical Specifications Of Rolling Shutter Door Machine:

| Shutter Door Roll Forming Machine | ||

| 1.Formed Material | GI | Thickness:0.6-1.2mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 12 rows(As your requirement) |

| Diameter of shaft | 50mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | gear and Chain transmission or gearbox | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Siemens(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 15-45m/min(customized) | Speed is adjustable according to customer's request |

اللغة العربية

اللغة العربية