Full Automatic Tee Bar Making Machine

China homemade full automatic Tee Bar Roll Forming Machine, fll automatic version Zhongtuo cold roll forming machinery has two types Tee bar roll forming machines, half automatic version and full automatic version. Here I will show you some information about the full automatic version.

The reason why I called it full automatic version which means the machine can punch the bead and holes when it working. Compared with half automatic Tee bar making machine, it will save much time and workers.

The Composition Of Tee Bar Roll Forming Machine:

1.Decoiler

- Usage: It is used to support the steel

- coil and uncoil it in a turntable way.

- Passive uncoil pulled by roll forming system

- Loading capacity: 1.5T

- Uncoiling width: 300mm

- Inner diameter: 450-550mm

2.Feeding and leveling

This part will level coil to make sure it is neat clean and straight. Meanwhile the roller will punch dots at both side of the C channel.

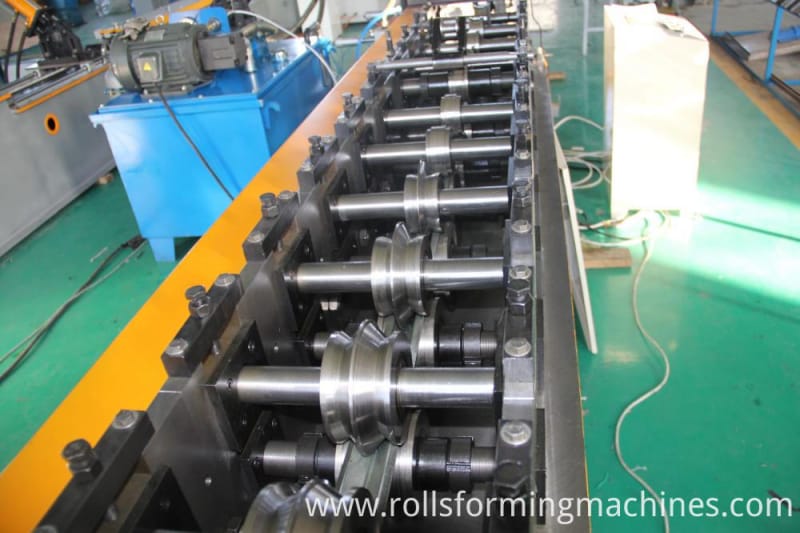

3.Roll forming machine

- Size: 5500х800х1400mm

- Weight : 2.8 tons

- Voltage:380V/50HZ3Phase(as

- customer`s request)

- Roller fixer : Guide column

- Frame : middle plate welded

- Memorial arch frame type

- Frame thickness:25mm

- Drive mode: gear

- Gear material: GCr12MoV

- Material of rollers: GCr12MoV

- Material of shafts: 45# steel with tempering

- Diameter of shafts: φ40mm

- Number of rollers :16 rollers

- Main power: 4kw

- speed:can be 25m/min

4.Shearing Machine

- Material of blades: Gcr12 quenched

- Power supply : hydraulic power

- Frame : Pillar style with rack & pinion system

- Stroke switch : non-contact photoelectric switch

5.Punchimg part

This part will punch the holes and the head auto.

- Material of mould: GCr12MoV

- power: 5.5kw

5.Hydraulic Station and Electric Control System

- Hydraulic motor Power: 4kw

- Hydraulic oil: 46#

- Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

- Other electric element are Delta

- Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

7.Some end product picture of our Half Automatic Tee Bar Roll Forming Machine:

Looking for ideal Tee Bar Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Full Automatic Tee Bar Machine are quality guaranteed. We are China Origin Factory of Tee Bar Making Machine. If you have any question, please feel free to contact us.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Ceiling Channel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu