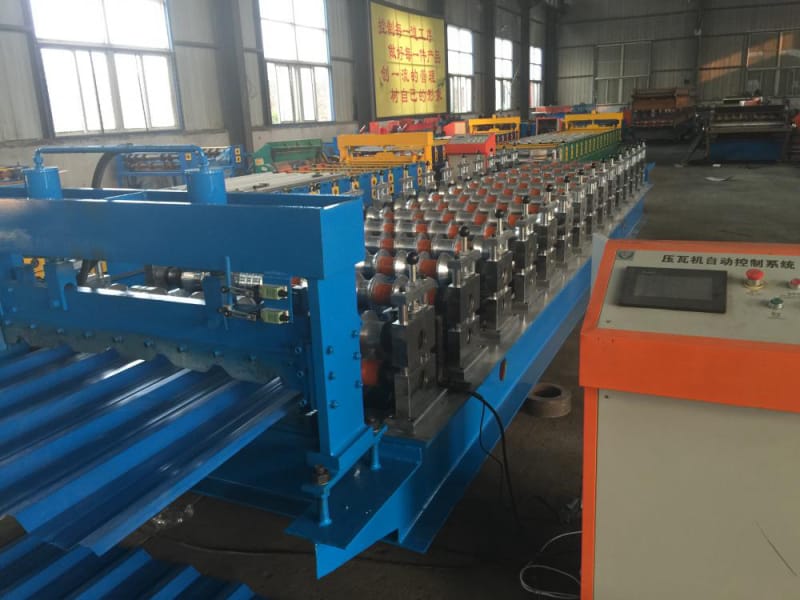

900 Tile Forming Machine, Steel Roofing Machine

900 Tile forming machine is widely using in all kinds of civil buildings, including stadium, garage, villa and so on.

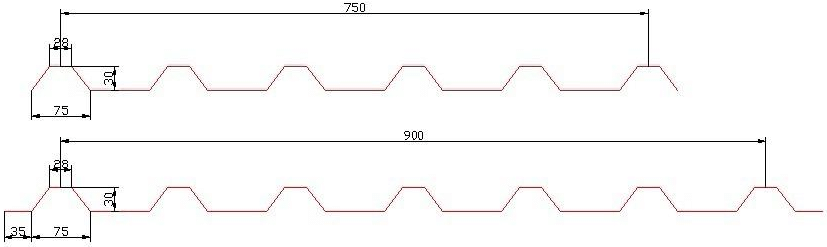

Drawings of roofing tile:

Material using in 900 tile forming machine

Processing material: colored steel plate, galvanized plate.

Material thickness:0.3-0.8 mm

Material hardness: 195 mpa---350 mpa

Coverage width: 900 mm

Coil width: 1200 mm

Forming speed: 8-12 m/min

Working flow of 900 steel roofing machine:

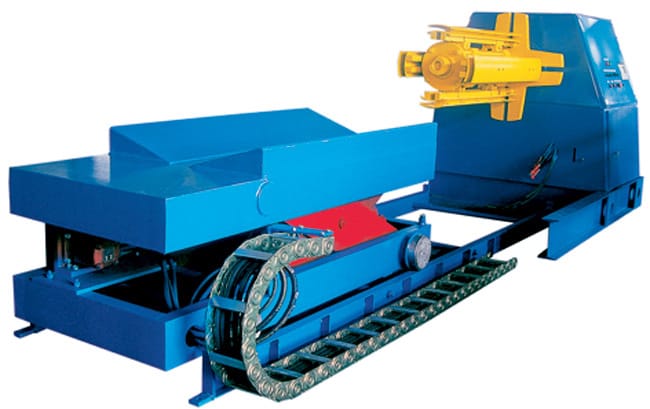

Uncoiler system:

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Loading capacity:5T

Uncoiling width:1000 mm

Inner diameter: 450-550 mm.

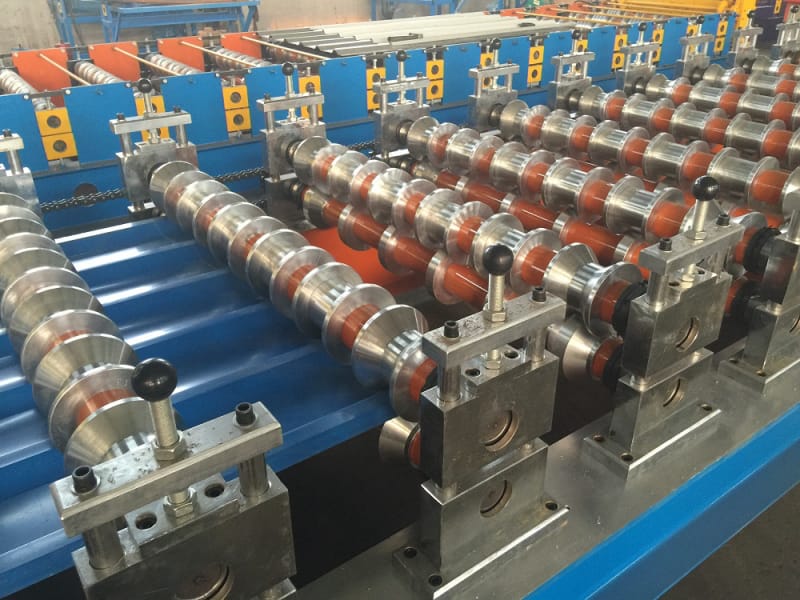

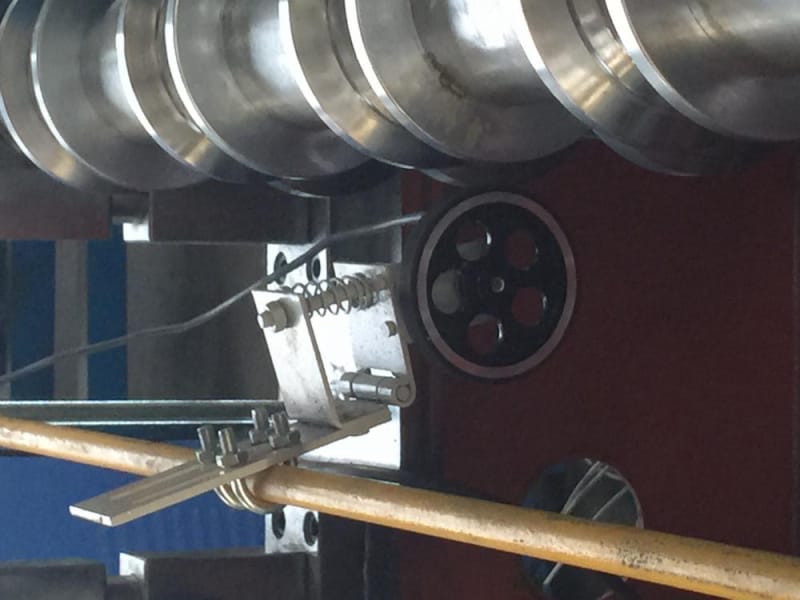

Main machine for roll forming:

Main specification of this parts:

Control System: PLC inverter

Main Frame: 350mm H-beam

Main Power:5.5kw

Hydraulic Power:4kw

Power Supply:380V, 3-Phase,50Hz

Forming Speed:8-12m/min

Roller Station:13 stands

Diameter of Shaft: 80mm, hardening and tempering HRC40-45 ℃

Frame Thickness:0.3--0.8mm

Material of Cutter: GCR12

Roller: 45# plating Cr , thickness of Cr 0.05-0.06mm, quenching HRC58-60 ℃

Total Weight:4.5T

Brand of Motor: mengniu

Cutting Machinism:

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine.

Stop to cut , Post cut cutting length tolerance: ±2mm

Cutting tool material: GCr12 with quenched treatment 58-62℃

Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

Power of the oil pump: 4kw Hydraulic oil: 46#

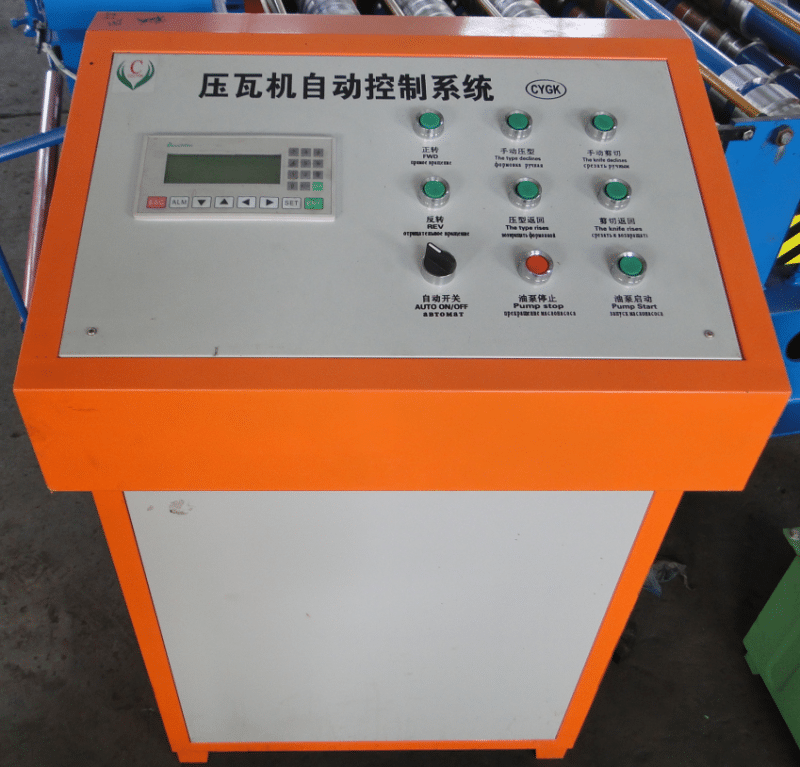

Computer control cabinet:

It adopts Delta PLC to control. The target piece length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one.

The system is easy to operate and use.

Processing precision : within 1.00mm

It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part.

Counter:

One counter gauges length, pulses, and decides length

Runout table:

3 m/set with 2 sets

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid

by T/T after inspection by buyer in seller`s factory while before delivery.

Delivery: 30 working days after receipt of advance payment

Service: we sent technician to your country to fix the machine.

The buyer should bear all the cost including: visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary50USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee.

Looking for ideal 900 Tile Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Tile Forming Machine are quality guaranteed. We are China Origin Factory of Steel Roofing Machine. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu